| |

|

|

| |

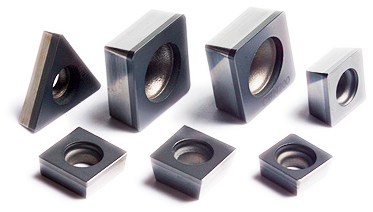

PCBN Inserts |

|

| |

|

|

| |

Our PCBN inserts are designed and manufactured to provide significantly longer tooling life, uniform surface finish and excellent dimensional control. As a direct result, all cost of the component can be significantly decreased, resulting in higher productivity as well as cost savings in the total manufacturing operation are successfully achieved. TACHEM manufactures a complete range of high quality PCBN inserts for machining ferrous materials. |

|

| |

|

|

| |

With the development of the CNC machining technology, the form and structure of hardened components are going to be more complicated and diverse. The PCBN inserts can meet the high efficiency, good stability, long life requirements. Therefore, we launched and designed series special inserts based on customers’ different requirements. |

|

| |

|

|

|

|

|

| |

|

|

| |

| |

|

|

| |

Advantages

- Consistent surface finish

- Good dimensional control

- High efficiency, reduce the machining time

- Stable performance, and improve the products’ quality

- Easily assembled, saving clients’ time

- Higher productivity, saving the cost

|

|

| |

|

|

|

|

| |

|

|

| |

| |

Tipped Inserts |

|

|

|

| |

|

|

- This kind of insert requires a carrier and substrate

- The tip parts are brazed to the substrate.

- The substrate need to have the pocket to support the tips

- As for these kinds of tools, the brazed joint area is weak, so it is very important to choose the brazing operation, and the inserts should be carefully controlled and executed

- Compared with the full-faced inserts, the main advantage is the lower cost

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

Full-Face Inserts |

|

|

|

| |

|

|

- The insert is made of presenter carbide and PCBN joint

- No brazed joint and delamination

- Better heat absorption capacity

- Higher heat resistance than tipped tools

- Larger cut depth compared with the same PCBN tipped inserts

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

Solid Inserts |

|

|

|

| |

|

|

- The solid inserts are made only of PCBN

- No material or brazed joint

- Best heat absorption capacity than others

- Very highest temperature application

|

|

| |

|

|

|

|

|

|

| |

|

|

| |

| |

|

|

| |

Application |

|

| |

|

|

| |

|

|

| |

|

|

| |

The PCBN insert can be used in CNC turning operations for finishing precision hardened material parts,a highly polished surface can be achieved when using PCBN inserts. Our PCBN inserts are specially geared toward aerospace and automotive applications.

Please ask us with your specific needs. |

|

| |

|

|

|

|

|

|

| |

|

|